This is a plant of PepsiCo, where chips Lay?s are produced. It has been opened recently in the city Azov of Rostov region. Let?s go over the whole sequence of production.

Peeling, assortment and cutting potato

Before potatoes go to the cutting machine workers check if there are any defects on the vegetables or not. If there are some they are cut out.

There are special sorts of potato, which are acceptable for chips-making, such sorts have higher content of starch.

All the workers regularly have a medical and a certificate that they are healthy, and they all wash their hands before working.

Peeling does in the abrasive barrels with periodical moving. First needed quantity of potato is weighed in a special bunker to go to the barrel.

Cutting, each piece shouldn?t be thicker than 2mm.

The very ?heart? of chips production line ? a frying bath. The whole world has no analogous equipment, it has been made specially for PepsiCo and forbidden to be shown.

Thin potato pieces are fried during 3 minutes at temperature 180 degrees Celsius. Oil and potato of high quality ? guarantee of good taste of chips.

Check of quality is necessary daily.

That?s the stage when all additives are added to the chips. Their main constituent is salt.

Chips of three different tastes maybe made simultaneously.

Packing.

The factory may produce 50 thousand tons of ready product annually. Sounds fantastic!

As you may see not many people work here. The process is automated. It?s for the better, none of us would like to know that different people have touched your food?

Precise weighing

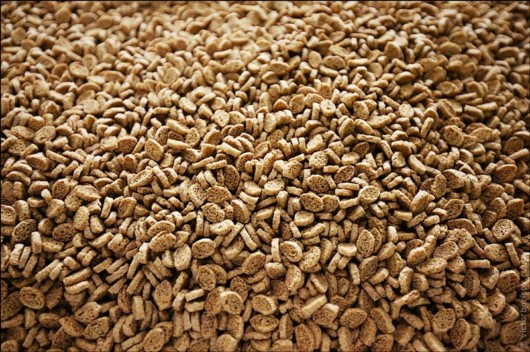

Dried crust production at the same factory

12 tons of ready product each day

Stuff of the factory

The factory itself

Bon appetit!